What must be done before the production of the wire saw machine has a huge impact on the production. Now Wanlong Machinery will explain the preparation for the use of the wire saw machine.

1. Punch holes:

Punching is a key preparation work. If the hole is not punched well, it will directly affect the penetration of the beaded rope, affect the service life of the rope and the cutting efficiency, so the process of punching is particularly important. Drill three holes, one vertical and two horizontal.

2. Thread the rope through the hole:

At present, when using beaded ropes in the domestic stone industry, most of them use the manual rope threading method, that is, fix one end of the rope with a multi-strand loop cord, thread it through one hole, and lead it out from another hole with iron wires, so that the beaded rope is passed through.

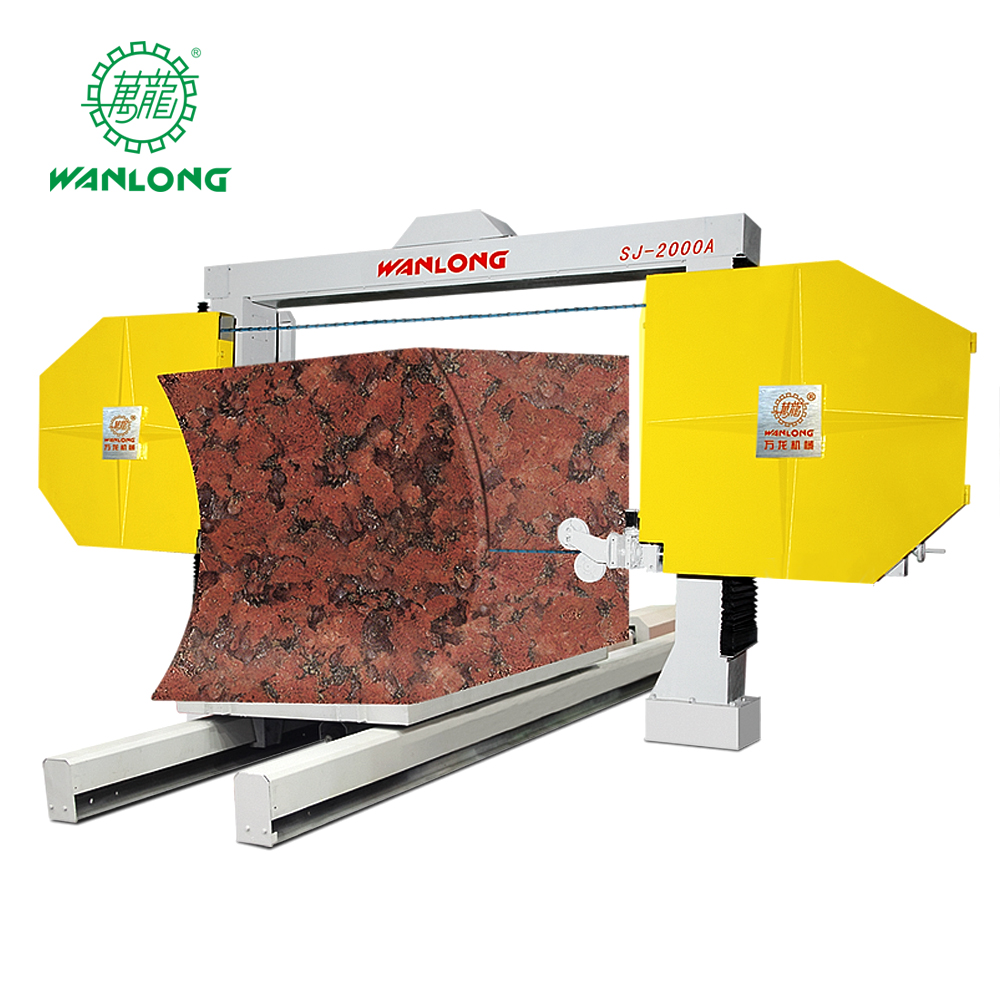

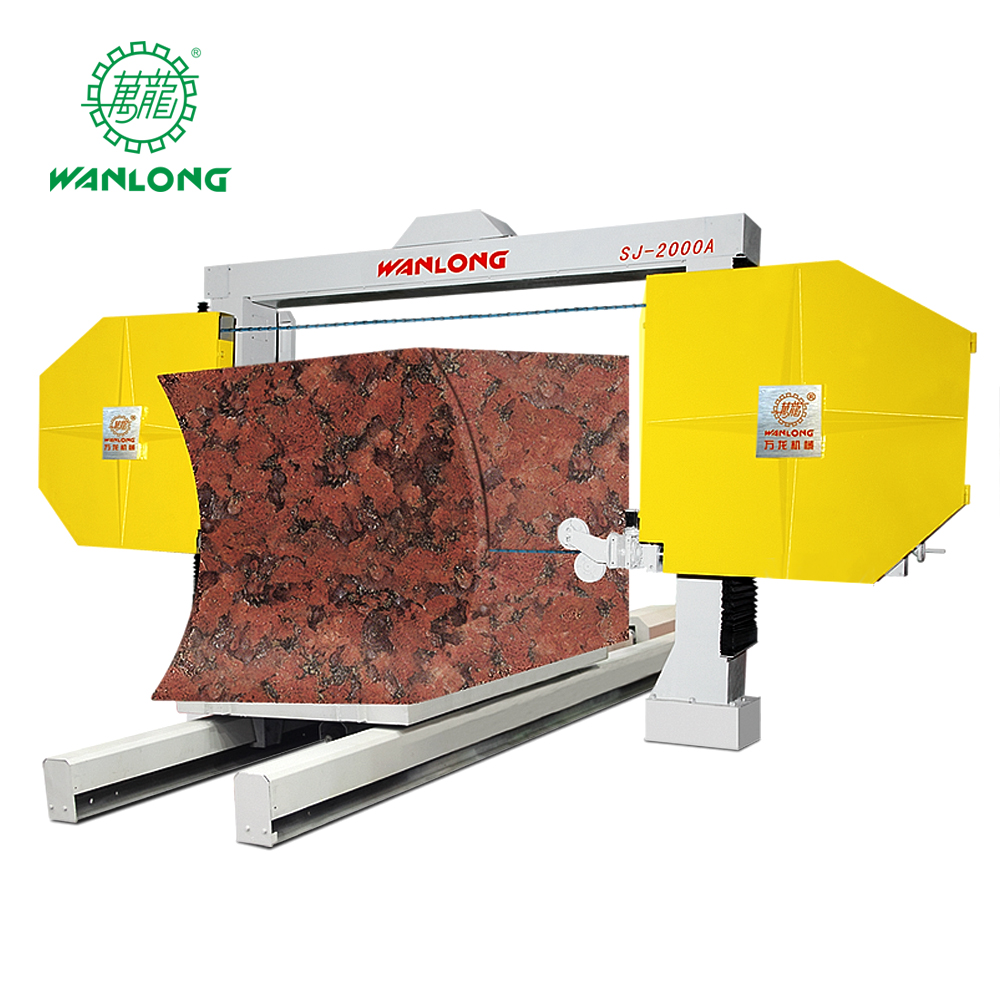

3. Installation equipment:

After the beaded rope is passed through, the equipment is installed. Because the equipment is heavy, and after cutting a plane, the equipment needs to be readjusted, so a lifting device must be equipped around it, which can be lifted and installed at any time.

4. Water supply:

When cutting the stone, due to the high linear speed of the rope, the friction between the rope and the stone is large. If water is not added or not enough, a large amount of heat will be generated between the rope and the stone, which will not only deform the spring and wire rope, but may even melt the spring and stick it. Knot together and lose elasticity, which will reduce the service life of the beaded rope. In order to ensure the quality and life of the rope, water must be supplied, and the water must be added along the movement direction of the rope.