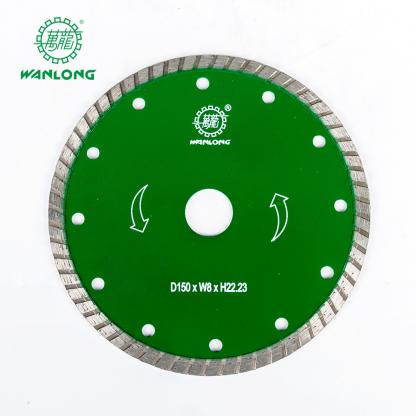

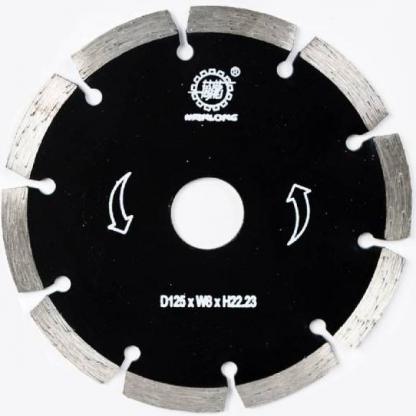

The specifications of Porcelain Diamond Blades produced by Wanlong are: 100mm 110mm 115mm 125mm 150mm 160mm 165mm 180mm 200mm 210mm 230mm 250mm 300mm 305mm 350mm, etc.

“FAN” Eege Cutting Blade For Porcelain(RF)

Other specifications are available upan request.

“FAN” Eege Cutting Blade For Porcelain(RF)

| Diameter(mm) | Steel core(mm) | Head size(mm) | No. | Shape | Application |

|---|---|---|---|---|---|

| 300 | 1.8 | 41.3/38.8×2.4×10 | 23 | RF | Porcelain |

| 350 | 2.2 | 42.7/40.3×3.0×10 | 26 | RF | Porcelain |

Silent and non-silent blades are available for choice.

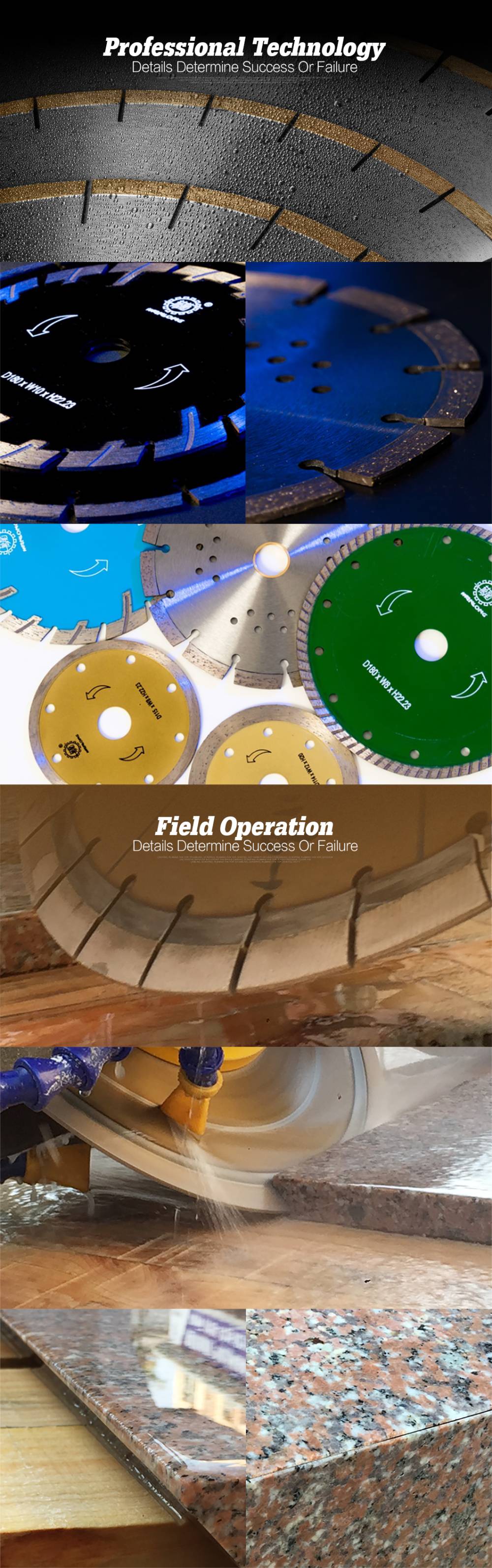

Product Advantages of "FAN" Eege Cutting Blade For Ceramic(RF)

1 Good continuity,effectively reduce the distance between teeth,cutting edge does not collapse.

2 The blade has good sharpness and high efficiency at the process of cutting.

3 Application: Porcelain, Ceramic, Microglass

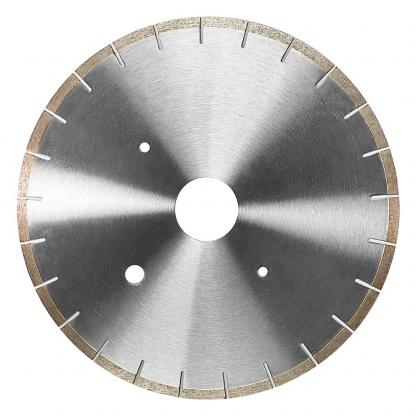

Continuous Rim Blade

| Diameter(mm) | Segment Dimension(mm) | Born/mm |

|---|---|---|

| 105 | 1.8×8.0 | 16/20 22.23 25.4/50 |

| 110 | 1.8×9.0 | 16/20 22.23 25.4/50 |

| 115 | 1.8×8.0 | 16/20 22.23 25.4/50 |

| 125 | 1.8×8.0 | 16/20 22.23 25.4/50 |

| 150 | 1.8×8.0 | 16/20 22.23 25.4/50 |

| 180 | 1.8×8.0 | 16/20 22.23 25.4/50 |

| 200 | 2.0×8.0 | 16/20 22.23 25.4/50 |

| 230 | 2.0×9.0 | 16/20 22.23 25.4/50 |

| 250 | 2.4×8.0 | 16/20 22.23 25.4/50 |

| 300 | 2.2×8.0 | 16/20 22.23 25.4/50 |

| 350 | 2.6×8.0 | 16/20 22.23 25.4/50 |

| 400 | 2.8×8.0 | 16/20 22.23 25.4/50 |

Product Advantages of Continuous Rim Blade

1. Good continuity,good cutting sharpness and high cutting efficiency.

2.This product is widely used for cutting and nondestructive grooving on marble, granite, Porcelain, ceramic, tile, concrete, decorative material, used on manual cutting machine.

3.Suitable for wet cutting.

Packaging & Shipping

Urgent order with Less weight or samples, we recommend courier service;

Normal (regular) order which weight over 45kgs, we recommend air cargo;

Big diameter saw blades or heavy weight, we recommend shipping by sea.

Wanlong will give the advice according to the actual order requirements.

Our Services

a. Every details will be confirmed with you before production;

b. Fine material will be selected for tool producing;

c. Each processing would be done by our skillful worker;

d. Our experienced QC will check the products piece by piece before packing;

e. We will keep you update of the order and shipping status untill you get the tool products smoothly.