Today, I will introduce the positioning standards and common specifications of big stone cutting machine price - stone machine manufacturer:

When the saw blades of the stone cutting machine are installed, they are divided into various types of saw blades. The common ones are 1600 mm, 1800 mm and 2200 mm. The price of the cutting machine also has a certain relationship with the size of the saw blade. Of course, the price of the longer length is higher.

Next, let’s talk about the price of the stone cutting machine and the choice of the size and specifications of its installation. Generally speaking, the manufacturer recommends the stone processing size of 11000mm×7000mm, which is 3 cubic meters for the saw blade. It is possible to install the above three types of diamond saw blades.

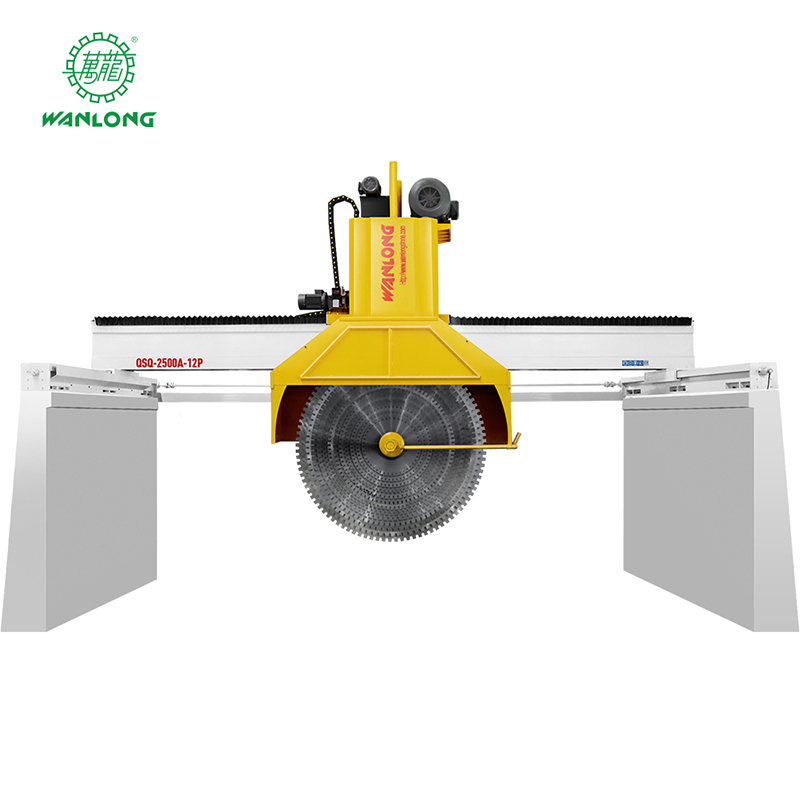

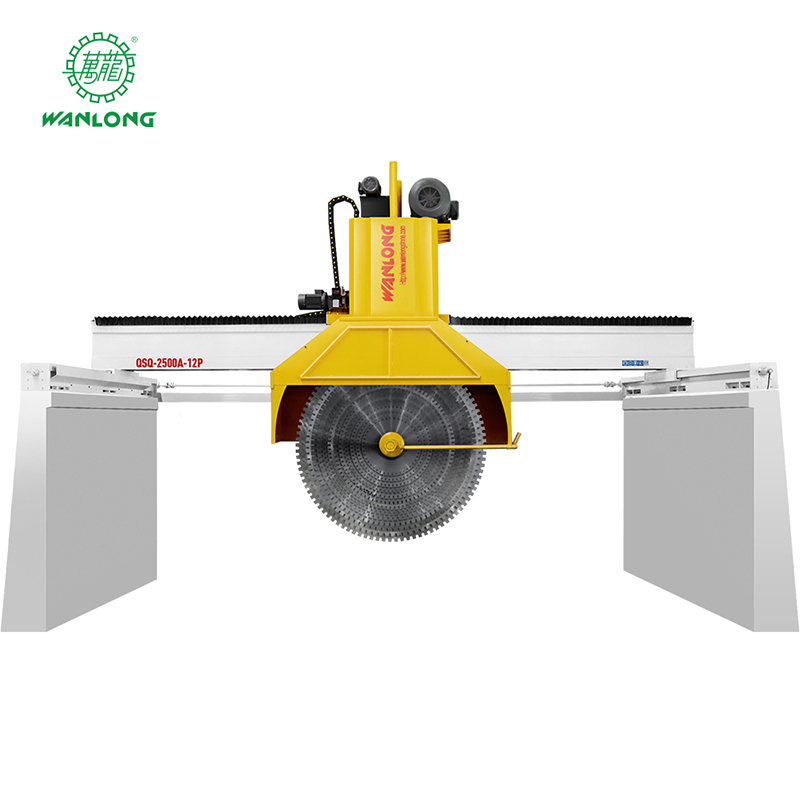

For the entire mechanical structure of the stone cutting machine, including a frame consisting of two columns fixed on the bottom plate and an upper beam connecting the top of the two columns, the price of the stone cutting machine also has a certain standard. The main features are: the left and right saw wheels are installed on the left and right axle seats through the left and right axles, the left and right axle seats are integrated with the sliding sleeve that can slide along the column, and the left and right sliding sleeves are provided with locking The left and right sliding sleeves are connected into one through the middle beam, a motor for driving the left saw wheel is installed on the middle beam, a saw blade is installed between the left and right saw wheels, and a double output shaft motor is installed on the beam on the frame to drive the left and right The worm, the left and right worms drive the left and right worm gears, the left and right worm gears each drive a wire machine to adjust the left and right sliding sleeves, the left and right wire machines are connected to the left and right sliding sleeves through a wire nut, and one end of the above-mentioned saw wheel has a belt There are bosses, and the angle between the left and right wheel axis lines is less than 100 degrees.

Therefore, if you want to understand the positioning standard of the stone cutting machine price, it is indispensable to look at the choice of product specifications.

Our mission is to provide customers with advanced technology solution to efficient stone processing. With 30 years' practical experience in the stone machinery industry plus rich experience and technological advantage of diamond tools, Wanlong will fit the needs of customers and help customers to create more revenue .

The main products are PLC-400/600/700 laser bridge cutting machine, QZQ-1200 middle bridge cutting machine, QSQ-2200/2500/300 multi blade block cutting machine, LXM-12/16/20 stone polishing machine, MS- 2600/3000 manual polishing machine, WLCNC-500 Four AXIS Cutting Machine, LMQ-2200/2500 block cutting machine and so on.

Quality first is our company's purpose the company set up a professional quality control Department, equipped with advanced testing measurement equipment, strict testing process, from raw material purchase to finished product warehouse; various processes are strictly controlled, to ensure that manufactured products were superior. Prompt and reliable after-sales services is also guaranteed by Wanlong. A well-organized after-sales services team provides all-round services covering from stone factory designing, machine installation, maintenance, supply of spare parts and market research for decision-making and production.

Now we are exporting to Middle-east, East-Europe, Asia, Africa and other parts of the world. We look forward to establishing business with you for mutual benefits.