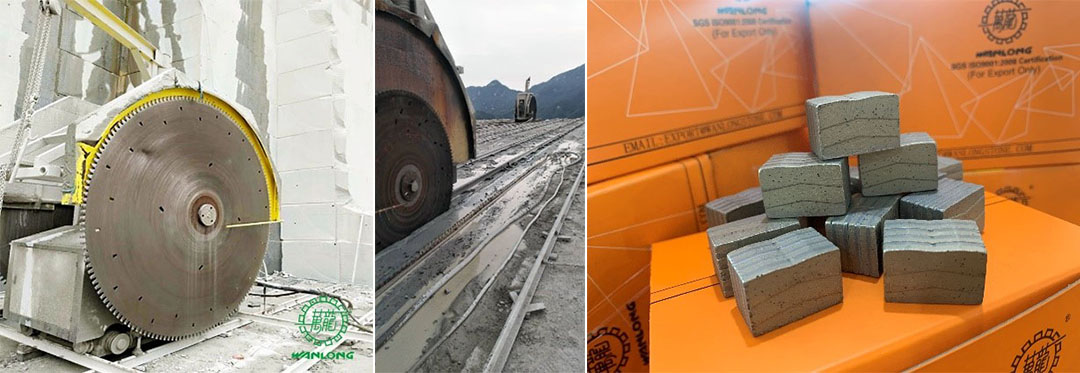

High cutting efficiency

Cutting is a critical process in stone production and processing. A high-quality segment must first demonstrate efficiency. If efficiency is low, with excessively slow feed rates and cutting speeds, it reduces production efficiency for slabs, thereby increasing production costs—such as labor wages, electricity, and water expenses—and directly impacts subsequent processes. Therefore, efficiency is paramount for diamond segments; a segment lacking cutting efficiency is absolutely not a good segment.

Long Cutting Life

A diamond segment with extended service life can reduce processing costs, such as welding expenses, labor costs, and procedures like blade replacement, sharpening, and testing. For stone factories, cutting more square footage at the same efficiency level is highly significant.

Optimized Segment Design

The segment's shape primarily enhances sharpness, increases water channels for improved coolant efficiency, and facilitates chip evacuation. A segment meeting these functional requirements is considered high-quality. Conversely, suboptimal design leads to cooling and chip removal issues, causing various operational problems.

Fast Grinding Speed

This characteristic correlates with diamond segment efficiency. However, grinding speed impacts more than just cutting performance. At rotational speeds, a segment with high grinding speed enables the saw blade to cut stone effectively without requiring excessively high RPMs. Moreover, this rapid grinding minimizes the risk of stone chipping or slab fractures.

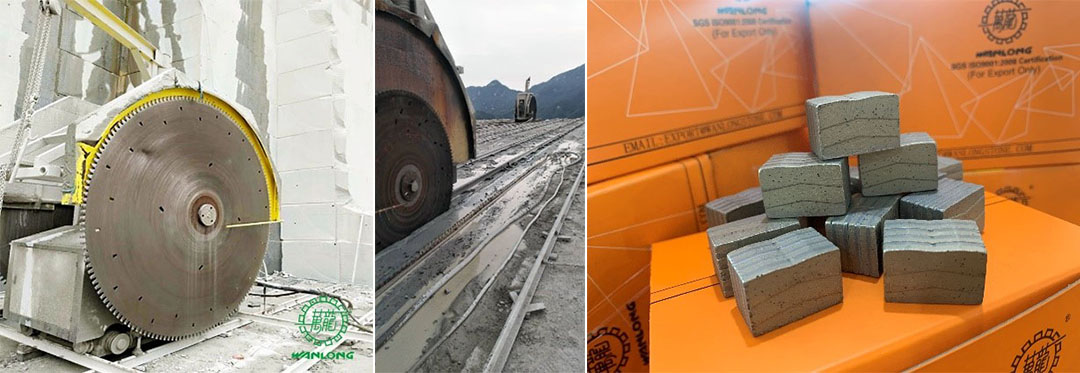

Well-designed segments

Examining a sharpened diamond segment reveals clearly exposed diamonds on its surface, often with distinct trailing edges. This structural design enhances segment stability and sharpness.

High-cobalt copper-based formula for superior segments

These diamond segments exhibit a yellowish hue, resist rusting, and feature robust bonding—making them ideal for cutting premium marble. In contrast, inexpensive segments often appear whitish and prone to rusting, which can contaminate the stone.