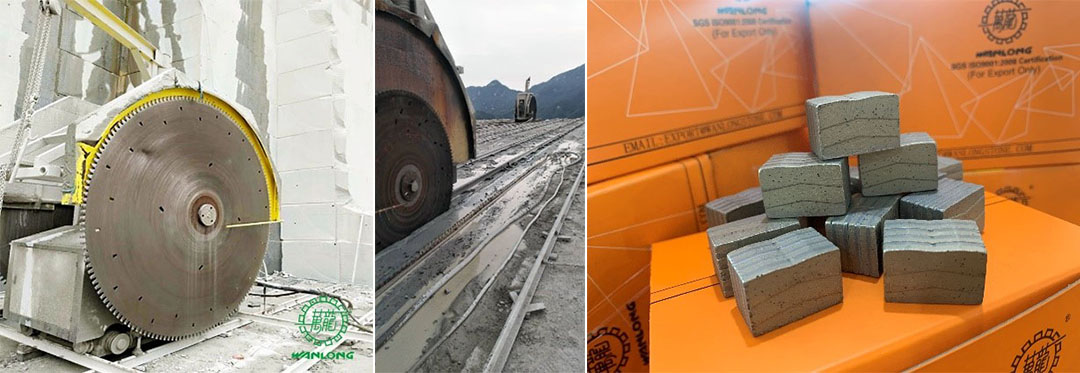

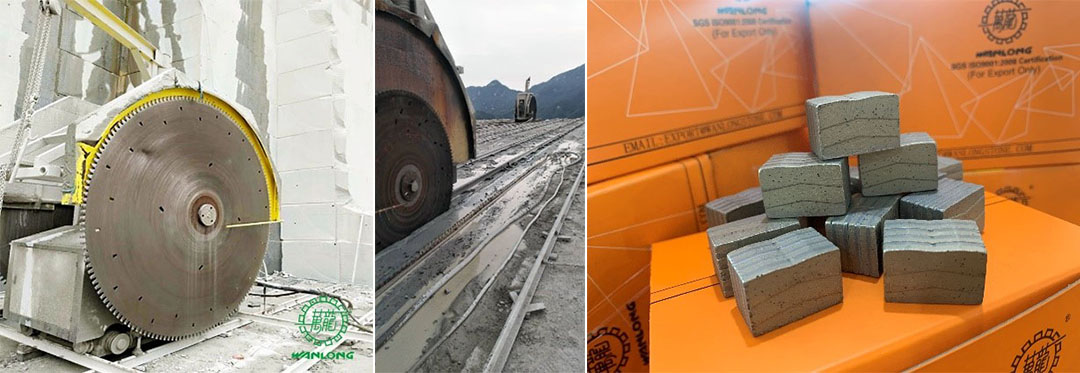

The most common use of diamond segments is welding them onto saw blade bases for cutting materials such as stone, tiles, asphalt, and concrete. However, did you know that the segment determines many factors of the saw blade, such as its lifespan, sharpness, and stability? So, what determines these key aspects of the segment?

1. Diamond Grit Size

Diamond grit size is a very important parameter of the diamond segment. Generally, when coarse-grained segments are used on saw blades, the segments are sharp, the cutting efficiency is high, and the cutting life is long. However, the bending strength of the diamond segment decreases, and the segment is prone to deformation and shedding when encountering overly hard materials. If a mixture of coarse and fine grit sizes is used, the segment will be more durable, but the cutting efficiency will be lower. If only fine-grained diamond segments are chosen, the segment will be very durable, but the cutting efficiency will be further reduced, which is why it is widely used in hard granite processing. This is also one of the reasons why granite segments are cheaper than marble segments. Of course, when choosing the diamond grit size, particles with a size of 50/60 mesh are more suitable.

2. Diamond Concentration

Diamond concentration refers to the content of diamond powder in a certain volume. The higher the concentration, the more diamond material is used. As the diamond concentration increases, the sharpness and cutting efficiency of the saw blade gradually decrease. This is mainly because there are more diamonds on the cutting surface, and with a constant cutting speed, the larger the cutting surface, the slower the cutting efficiency. However, as the diamond concentration increases, the service life of the segment will gradually increase. However, a higher diamond concentration is not always better. In fact, when the diamond concentration is too high, the saw blade will not create new cutting edges due to the strong impact and friction because the cutting surface is too large. When the friction surface becomes blunt, the diamond segment will no longer be able to cut the stone. Conversely, as the diamond concentration gradually decreases, the efficiency of the saw segment will continuously improve. However, in terms of lifespan, due to the reduction in the cutting surface, the matrix binder will be rapidly consumed, naturally leading to a significant decrease in lifespan. When the diamond concentration drops to a certain level, the segment will no longer be able to cut the stone. The main reason is that the cutting surface is too small, and the diamonds are worn down as soon as they come into contact with the material, causing problems such as inability to cut.

3. Diamond Strength

The diamond strength needs to match the hardness of the material being cut. A diamond hardness 1-2 Mohs higher than the material is optimal. Diamonds with excessively high strength are difficult to break, and the abrasive particles are polished during use, reducing sharpness and leading to cutting slippage. Conversely, if the diamond strength is insufficient, it is easily broken after impact and cannot withstand the heavy cutting load. Ideally, for ordinary hard granite, a strength of 130-140N is preferred.

4. Bonding Matrix

Currently, copper-based bonding matrices are commonly used for marble. Because marble is relatively soft, the mechanical performance requirements for the segment are lower. Copper-based binders have characteristics such as low wear resistance, low strength, and low sintering temperature, which maximize the integrity and abrasiveness of the diamond material in the segment. Granite, however, is different. Granite is harder and has higher abrasiveness. Choosing an iron-based binder allows for higher segment strength, and because iron and diamond have a natural affinity, the iron-based segment can increase the holding power of the diamond during use, allowing the diamond segment to cut harder granite. As for cobalt-based binders, they mainly improve the strength, hardness, and bonding performance of the segment, and are mainly used in gang saw segments or some higher-grade marble segments.

5. Sintering Process

As the temperature increases, the densification of the matrix increases, and the bending strength also increases. Furthermore, with the extension of the holding time, the bending strength of the blank matrix and the diamond agglomerates first increases and then decreases. A sintering process at 800℃ for 120 seconds can be chosen to meet the performance requirements.