Identify by shape

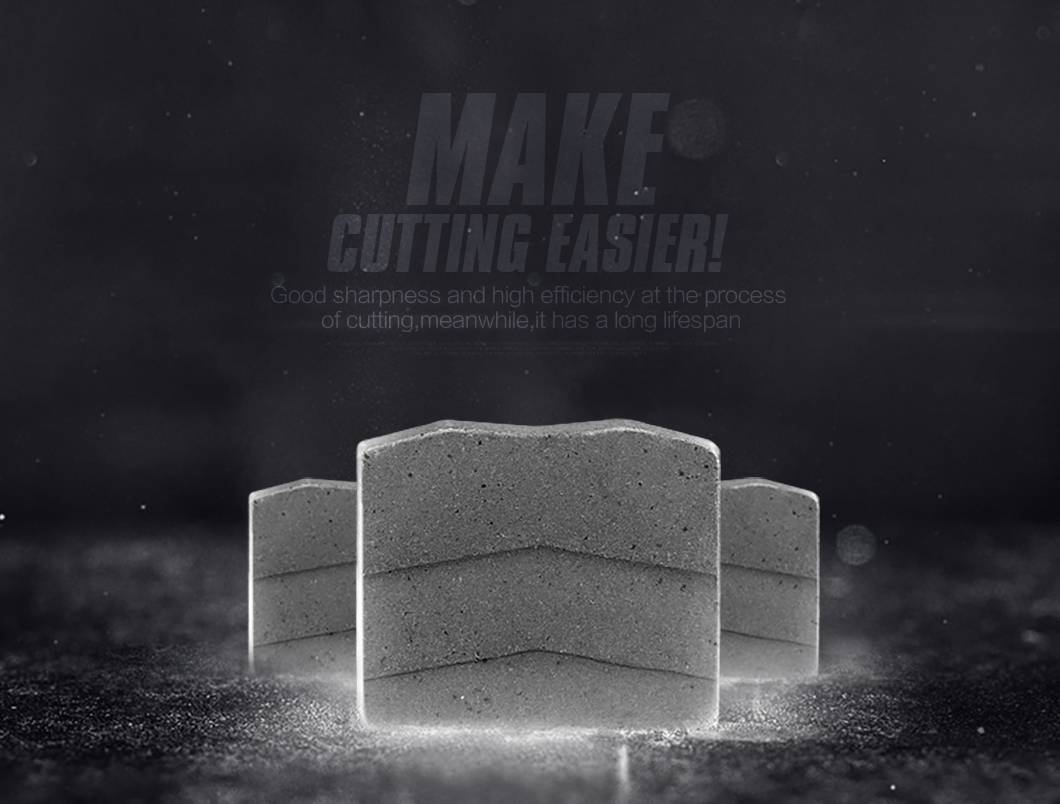

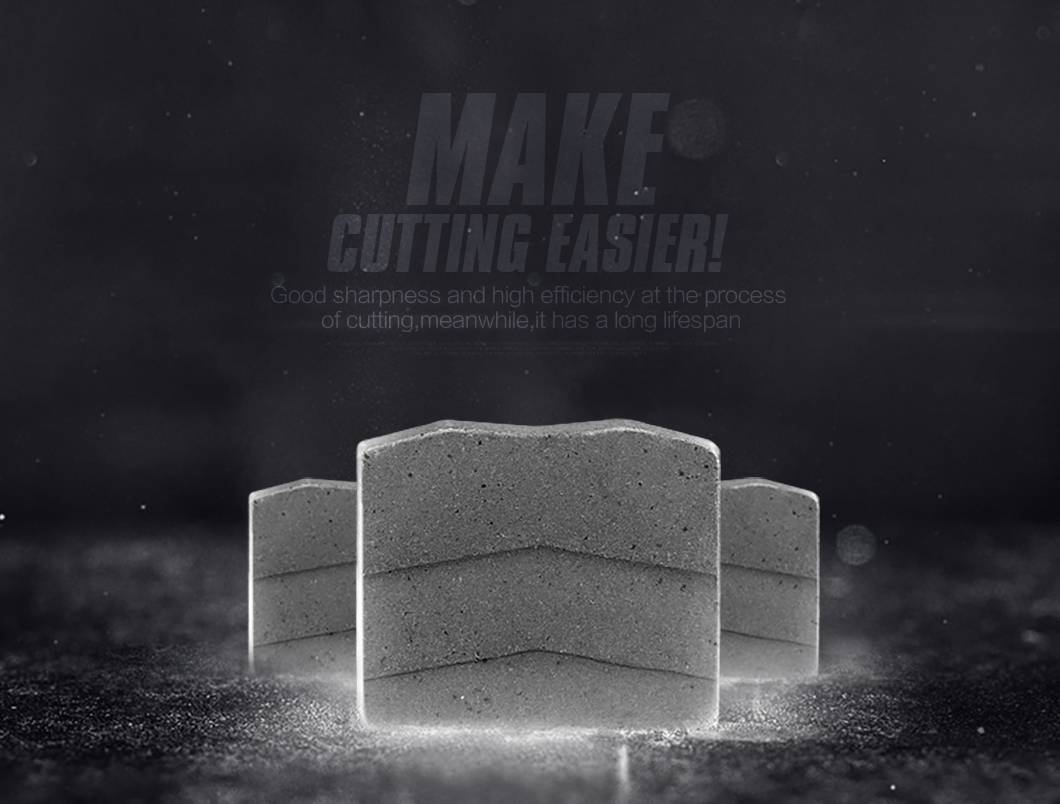

The granite segment will be designed into various shapes in terms of cutting edge to facilitate cutting, such as M-shaped, V-shaped, K-shaped, W-shaped, corrugated, fan-shaped, etc. Because the cutting area is reduced, therefore, this segment will be very difficult at the beginning. It is sharp, and in the early stage of cutting stone, it can be stably surpassed; while the marble segment is mostly cuboid and fan-shaped structure, mainly because the material of marble is highly abrasive, and the rectangular segment can be cut longer. Long life, and the marble material is relatively brittle, stable cutting is more conducive to the forming of the plate. Generally speaking, the shape of the marble segment is relatively simple, and the granite will adjust the shape of the sharper segment according to the characteristics of different stones to achieve sharper and faster. Cut effect.

Distinguish by structure

The marble segment is mostly a segment without interlayer or single-layer interlayer (interlayer structure) in structure, mainly because the marble material is soft, and the advantage of adding interlayer is to increase its sharpness. , so a simple one-piece segment and a single non-working layer segment are more conducive to improving the life of the segment, and can appropriately increase the cutting speed of the segment. The granite segment is different, and the granite segment currently has multiple segments. The segment efficiency is much higher than the non-interlayer segment, especially the large segment with 7 layers and 9 layers, which is widely used in multi-piece bridge combined cutting and single-arm combined cutting, which greatly improves the processing efficiency.

Identification by carcass material

The granite segment faces very hard stone, so the granite segment has extremely high requirements on hardness and toughness. Silicon carbide is currently the best choice, but the price of this material is high. The granite part has an iron base. The use of this material greatly reduces the price of granite segments. Therefore, most granite segments use iron powder, resulting in gray-black or gray-white. The marble segment is rust-proof and increases abrasiveness, so a relatively stable copper base will be selected from the principle of the carcass. In terms of color, there are tan, golden yellow and bronze. Of course, there are some exceptions, like the gang saw segment used to cut marble, which is made of cobalt. Base, white-grey.

The biggest difference between marble segment and granite segment is the selection of diamond powder. The marble part adopts coarse-grained, low-quality, medium-concentration diamond powder, and the granite part adopts fine-grained, medium-quality, high-concentration diamond powder. Of course, not all marble and granite segments are formulated this way, but the overall adjustment direction and trend are often consistent.