As a professional manufacturer of Machinery with more than 10 years experience , Wanlong Stone Machinery Co Ltd has a very professional R&D team which devotes to keeping upgrading newest technology ,combining with the first-hand market information to ensure that our technology and machinery is always at the top level and well satisfy market and customers’ requirement.

Besides providing Top-level and high-quality Machine , we also guarantee timely and reliable after-sales service. We have a mature and professional after-sales team to provide 24 hours services covering from installation ,maintenance, collecting customers’ feedback ,and providing solutions for the problems faced by customers when operating the machine ect . Here Sharing More information about the problems and solutions of the Stone Machine to help customers know how to solve some problems by themselves to better operate the machine

1. What causes the lower efficiency of the Wanlong QSQ Multi-blade cutter after using for a period time

- The loose of spindle nuts

- The loose of spindle pressing nuts

- The segment is not sharp enough

2. The problems of Slicing for Wanlong QSQ Multi-blade cutter

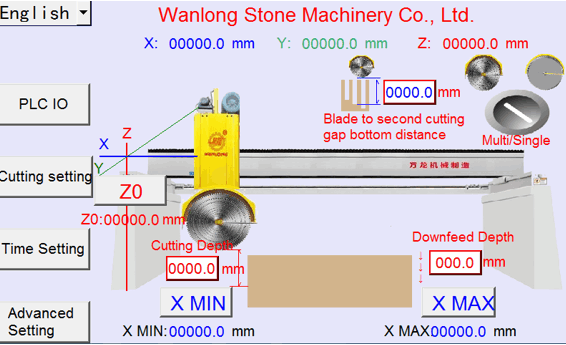

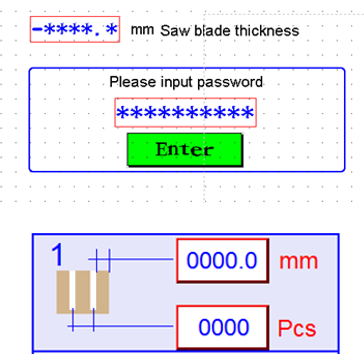

- If the tolerance of Slicing is same .please check whether the slab thickness and steel thickness on the screen is same as the actual thickness

If it is not same as actual thickness, please change the slab thickness and steel thickness on the screen

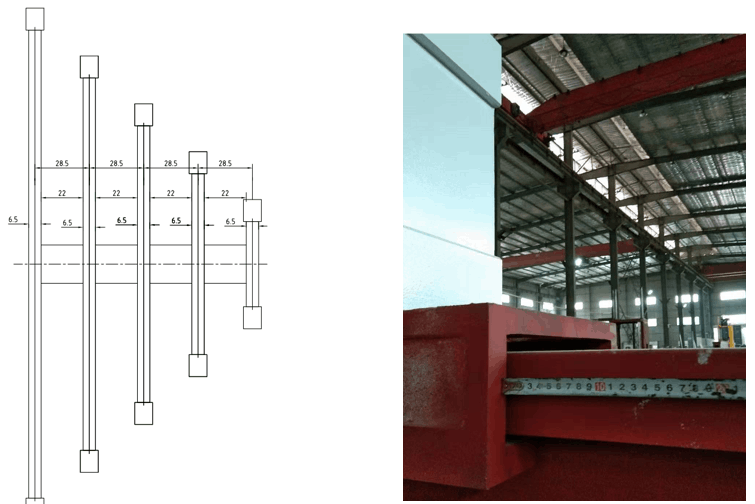

If it is same as actual thickness, please turn on the machine without putting the block on the table , change it into the automatic mode, measure the actual travelling distance of the side beam (check the pic as below) if the actual travelling distance is bigger or smaller than the total thickness of slab and steel , change the slab or the steel thickness to make the actual travelling distance same as the total thickness of slab and steel

- If the tolerance of slicing is not same , please check the below details

- .The encoder coupling is loose or not

- The encoder cable is broken or not

- Need to change the encoder or not

- The screw rod is worn or not

- The Nuts locked on the slide is loose or not

- The vertical beam on both sides is at the same level or not

3. Problem of the Screen for QSQ Multi-blade cutter

- Error for left and right coordinates(as below pic shown)

- Choose Manual Mode

-

Press the button of blade leftward till reach the position of the beginning of cutting , press the

Press the button of blade leftward till reach the position of the beginning of cutting , press the  to confirm the left limit. Then Press the button of blade rightward

to confirm the left limit. Then Press the button of blade rightward  until reach the position of the end of cutting , press the

until reach the position of the end of cutting , press the  to confirm the right limit

to confirm the right limit

- If the machine doesn’t move and the left limit is bigger than right limit , please follow the below steps to adjust it

- Choose Manual Mode

- Press the button of blade leftward

until reach the position of the left limit, press the

until reach the position of the left limit, press the  and reset

and reset - Press the button of blade rightward

until reach the position of the right limit , press the

until reach the position of the right limit , press the  and reset

and reset

- After resetting the left limit and right limit , the Error is still not solved ?

At this time , please check whether the Encoder wire is broken or in loose contact, if ok , please check whether the encoder is broken