However, when cutting, you need to pay attention to the following points, doing it well can make cutting easier.

1. Fix the water pipe at the designated position, place the water pipes at different cutting points, and open the water valve before the diamond beaded wire saw is started. The water supply must be maintained throughout the diamond wire saw cutting process.

2. Connect the industrial power supply (three-phase five-core 10 square cable) in advance and insert it into the power supply port of the electric wire saw cutting machine, check whether the power indicator light of the electric box of the distribution box is on, and turn the emergency stop switch on the distribution box at the same time. bounce.

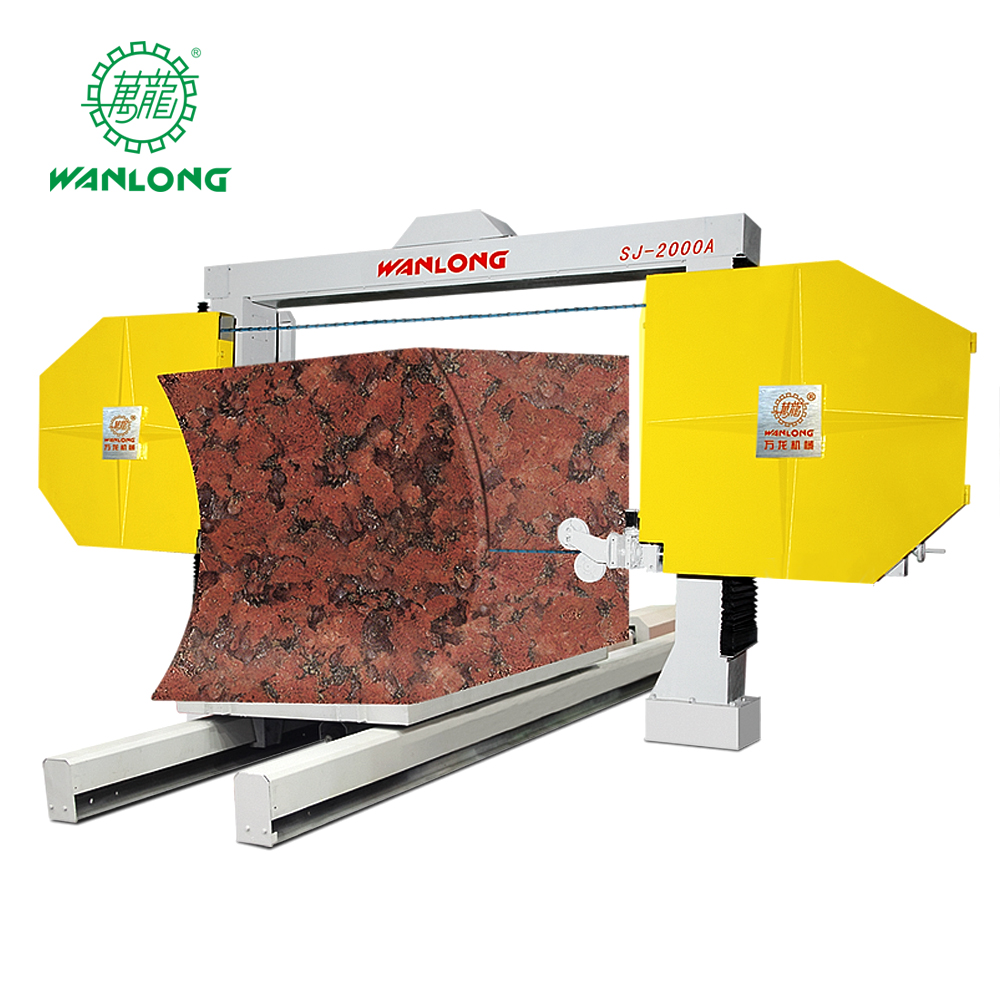

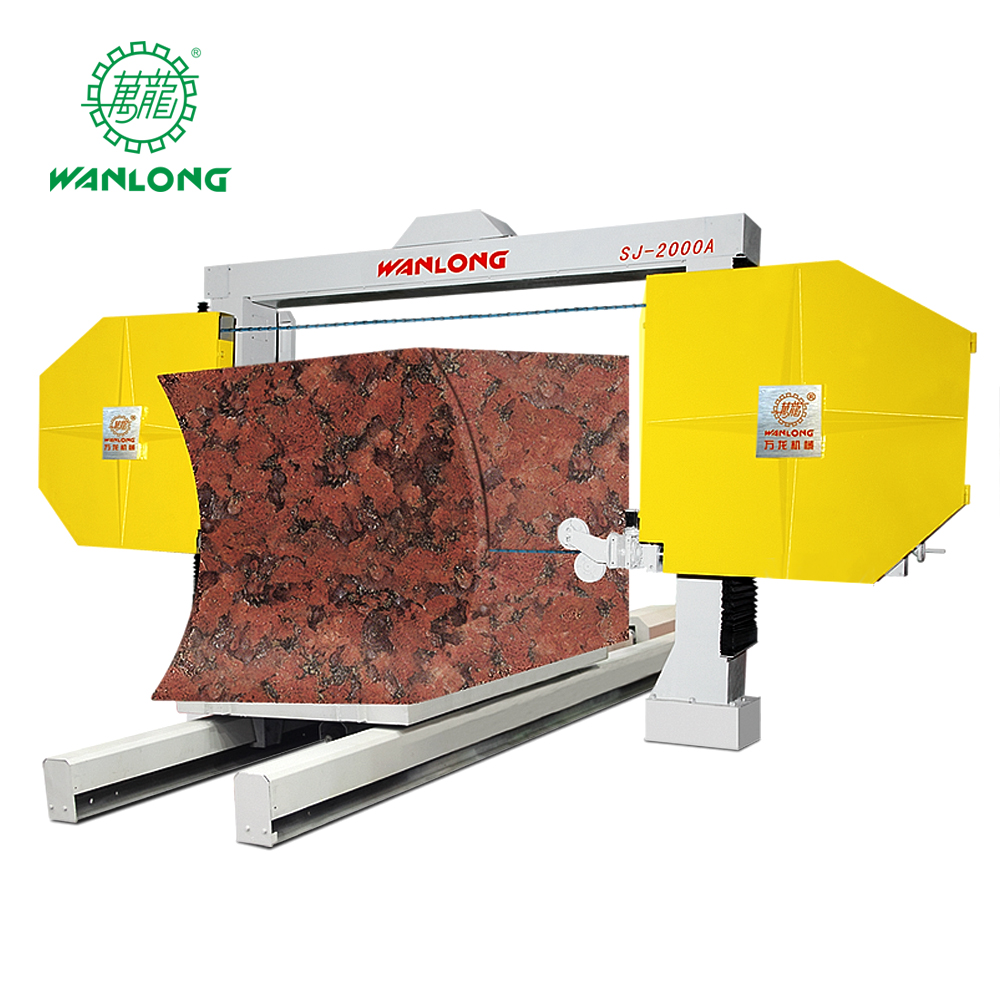

3. On the main machine of the concrete wire saw cutting machine, adjust the left and right or up and down reasonable positions of the guide wheel, the directional wheel and the main flywheel to ensure that the traveling direction of the diamond beaded rope is consistent with the direction of the large plate.

4. Thread the diamond beaded saw rope in the order of the holes, and note that the arrow direction of the diamond beaded rope should be consistent with the cutting direction of the wire saw.

5. Tighten the diamond beaded rope at 2~3 turns per meter, and use hydraulic pliers and crimping joints to crimp the diamond sawing rope to form a closure, and place the diamond rope on the driving disc.

6. Turn on the controller switch of the wire saw cutter.

7. Adjust the walking direction switch of the small motor control button to forward (FORWARD) or backward (BACKWARD).

8. Rotate the walking controller to control the walking speed to adjust the tension of the diamond beaded rope. When the tension of the rope meets the requirements, the controller returns to zero.