(1) Preparation before trial operation

Carry out a comprehensive inspection of the entire external connection and fasteners to confirm that they have been connected and fastened;

All reducers, headstocks, rotating parts, moving parts, etc. must be filled with lubricant according to regulations;

(2) Power-on inspection

Power on

Check whether each indicator is normal;

Check whether the emergency stop button is reliable and effective;

Note: This machine is controlled by a computer. You only need to perform lifting, slow and other technical operations on the control panel.

Infrared is an electromagnetic wave with a wavelength between microwave and visible light. The wavelength is between 760 nanometers (nm) and 1 millimeter (mm), which is invisible light longer than red light.

Anything above absolute zero (-273.15 ° C) can generate infrared rays. Modern physics calls it heat rays. Medical infrared can be divided into two categories: near infrared and far infrared. Containing thermal energy, the sun's heat is mainly transmitted to the earth through infrared rays.

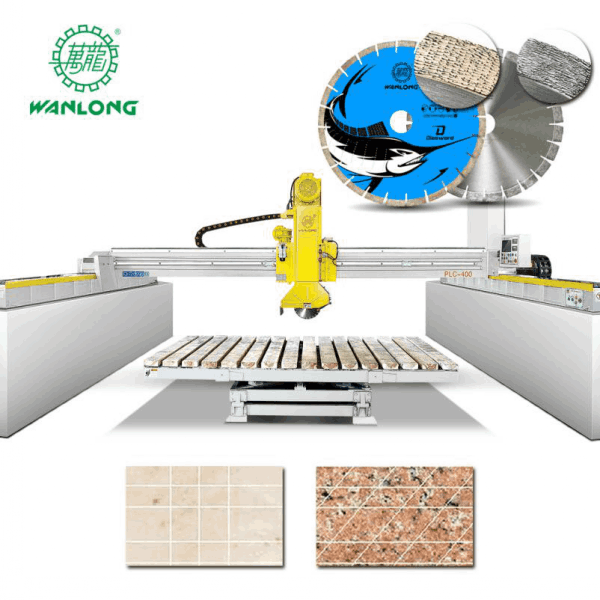

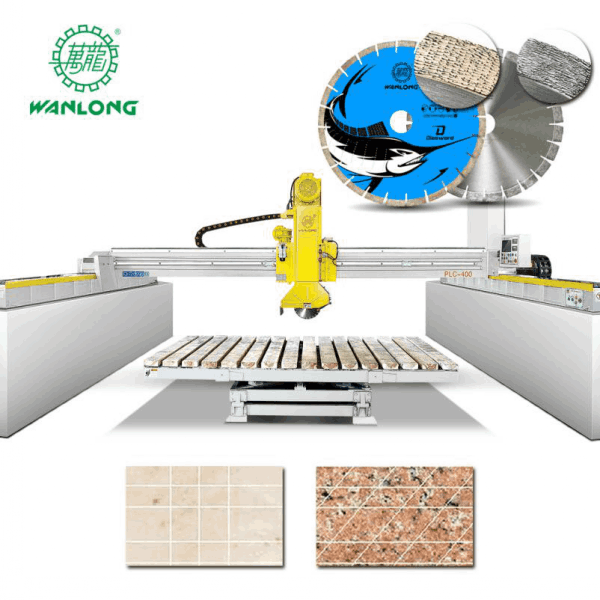

This article is excerpted from: granite cutting machine Manufacturer Wanlong Group

This article is excerpted from: granite cutting machine Manufacturer Wanlong Group