What is a diamond cutting disc

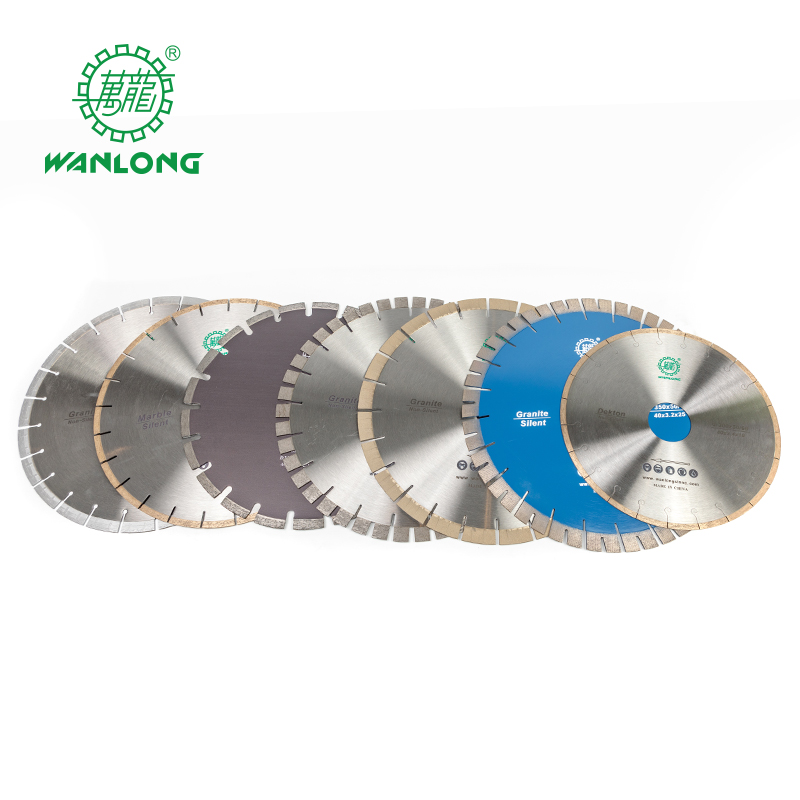

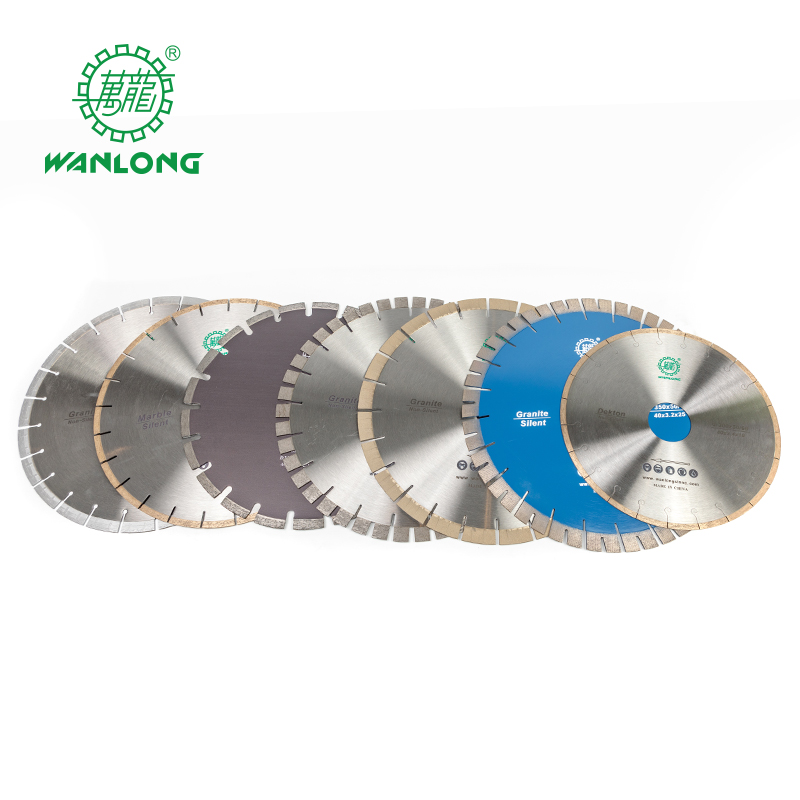

A diamond saw blade is a cutting tool, which is mainly composed of two parts; the matrix and the segment. The matrix is the main supporting part of the bonding segment.

The segment is the part that cuts during use. The segment will be continuously consumed during use, while the matrix will not. The reason why the segment can cut is because it contains diamond, which is currently the hardest. The material, which rubs and cuts the processed object in the cutter head. The diamond particles are wrapped by the metal inside the segment.

The use of diamond cutting discs

Diamond cutting blades are mainly used for sawing and cutting stone, and are widely used in the cutting of marble, granite, ceramic wall and floor tiles and finished concrete products. They are the primary processing equipment in the stone and building materials industry.

Can diamond blades cut metal?

Yes, there are many types of saw blades on the market, some are special for cutting stone, and some are special for cutting metal, the premise is that you must choose the right blade.

What is the life time of diamond cutting blades

The material of the cutting blade and the cutting method are one of the important factors affecting the life of the cutting blade. In addition, according to the test, the low-quality saw blade lasts for 11 hours in the long-term cutting process, while the high-quality saw blade lasts for up to 120 hours.

How to operate a diamond saw blade safely for cutting

When the saw blade is operated, it should be ensured that the workpiece is fixed, and the positioning of the profile should also conform to the direction of the knife to prevent abnormal cutting conditions.

Do not apply side pressure or curved cutting, and the feed should be stable enough to prevent the blade from impacting the workpiece, which may cause the saw blade to break or the workpiece to fly out, resulting in an accident. During operation, if If it is found that the sound and vibration are abnormal and the cutting surface is rough, the operation should be terminated immediately, and the inspection should be carried out in time to troubleshoot and prevent accidents. When starting and stopping cutting, be careful not to feed the knife too fast to prevent broken teeth and damage. situation.

When cutting aluminum alloys or other metals, special cooling lubricants should be used to prevent overheating of the saw blade, tooth paste problems, and other damage conditions, which will affect the quality of cutting.