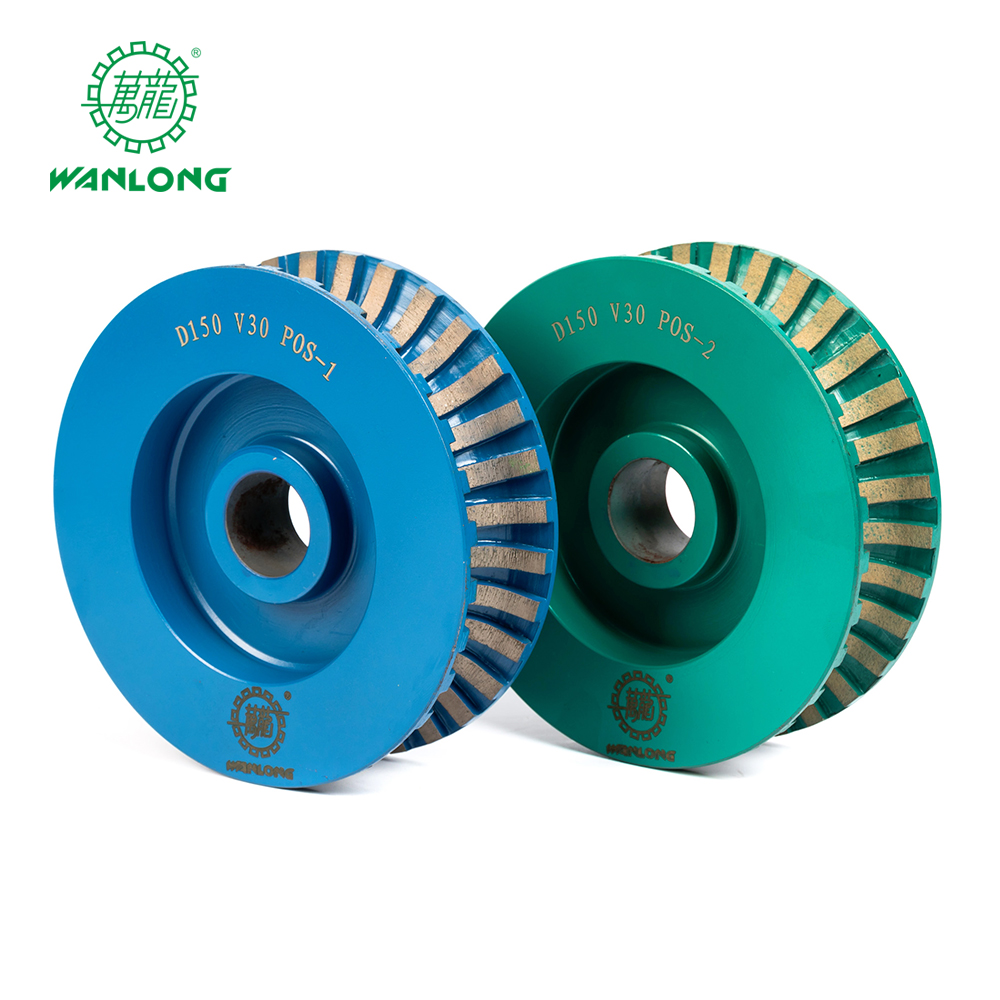

Due to the difference in abrasives, bonding agents and manufacturing processes, the characteristics of grinding wheels vary greatly, so they have an important impact on the processing quality, productivity and economy of grinding.

The characteristics of the grinding wheel are mainly determined by factors such as abrasive, particle size, bond, hardness, structure, shape and size. But the grinding wheel must be handled with care, otherwise it is easy to cause damage.

Grinding wheel storage and handling knowledge:

(1) Implement the principle of advanced use first to ensure the best service life of the product;

(2) The product can be used after rechecking the rotation strength and appearance after one year.

(3) Stack neatly, lay flat, and cannot be placed obliquely or under long-term pressure to prevent deformation;

(4) It must be fully packaged and transported to avoid collisions, and must not be damp for a long time, and must not be in contact with alkalis;

(5) To avoid direct contact with the ground, it must be stacked on a moisture-proof wooden pallet, preferably 10-15cm from the ground, and the stacking height should not exceed 1 meter.