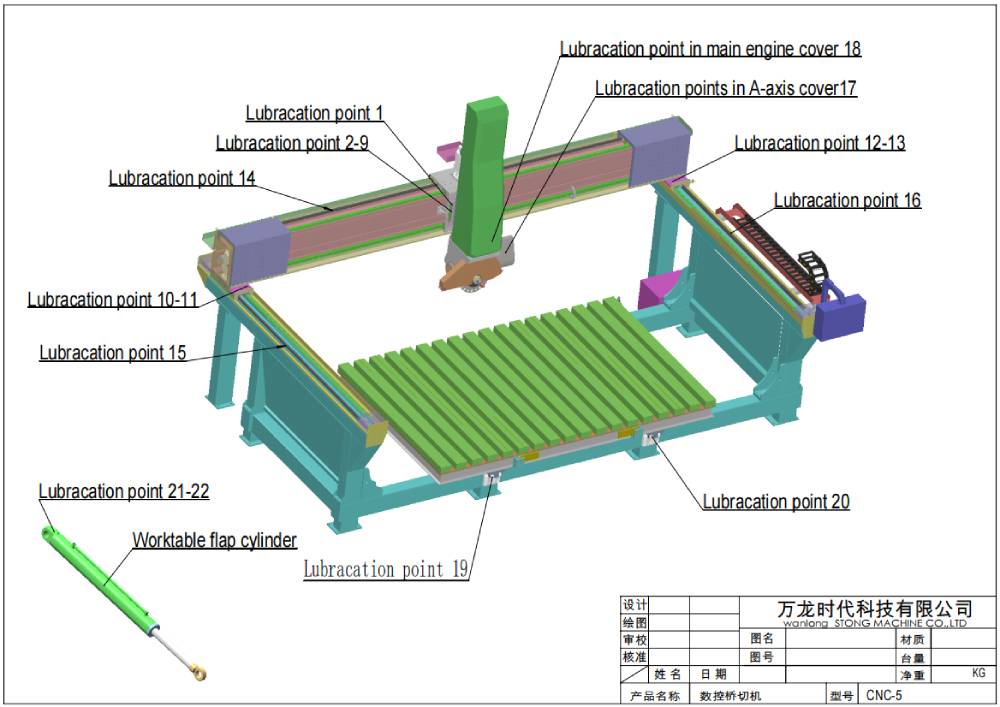

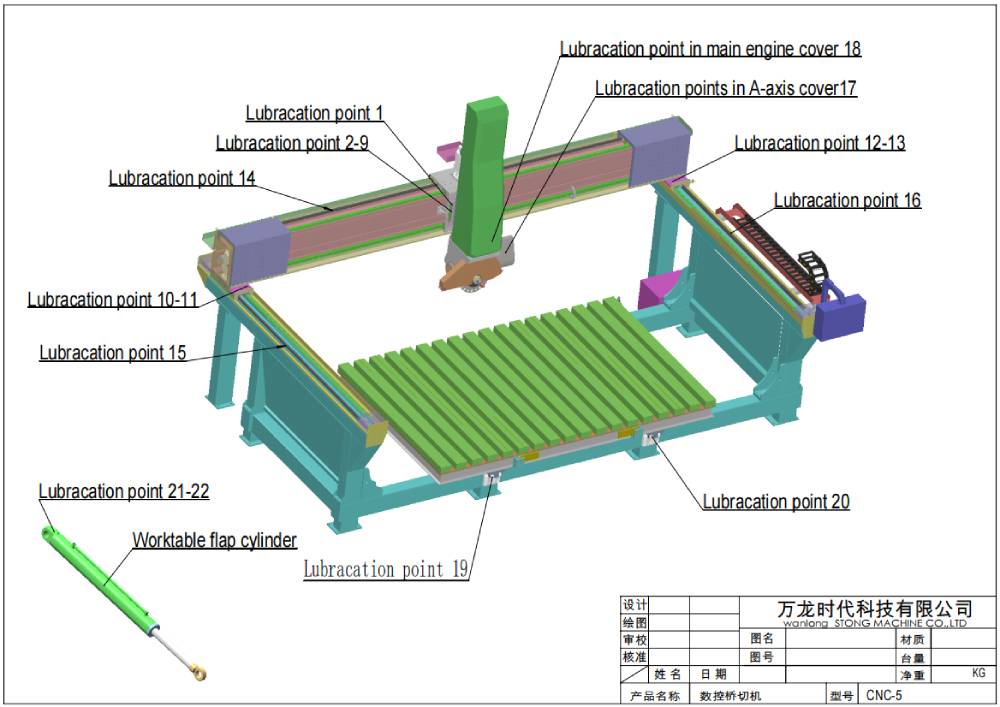

The core of maintenance is lubrication, waterproofing, anti-ash, anti-loosening and so on. The performance of a cutting machine is directly related to the operation of the lubrication system. The purpose of lubrication is to improve the resistance to friction between moving parts, prolonging their life, increasing the accuracy of parts, and ultimately reducing energy consumption.

Lubrication point(1-22) as below

Lubrication operation manual

| Lubracation point | Lubracation part | Lubracation grease | Lubracation period | Note |

| 1 | Lifting rod Screw | 0# lithium Base Grease | Add once every 1 months | |

| 2~9 | X,Z-axis linear slider | 0#lithium Base Grease | Add once every 1 months | |

| 10~11 | Y-axis linear slider | 0#lithium Base Grease | Add once every 1 months | |

| 12~13 | Y-axis linear slider | 0#lithium Base Grease | Add once every 1 months | |

| 14 | Cross beam rack | 3#lithium Base Grease | apply once every 1 month | |

| 15 | Left side beam rack | 3#lithium Base Grease | apply once every 1 month | |

| 16 | Right side beam rack | 3#lithium Base Grease | apply once every 1 month | |

| 17 | A-axis drive reducer | 00# lithium Base Grease | Replace after working 2000H | |

| 18 | C-axis drive reducer | 00# lithium Base Grease | Replace after working 2000H | |

| 19~20 | Work table hinge | 3#lithium Base Grease | Add every one year | |

| 21~22 | Work table oil cylinder | 3#lithium Base Grease | Add every one year |

2. Daily maintenance

2.1 In normal operation, the operator should consciously listen to the noise of the machine, observe the vibration and bolt looseness of the machine, and whether there is abnormal friction in the operation of the parts. If any abnormal phenomena occur, it must be stopped in time after asking the repair department or consulting engineers.

2.2 Operator should do the work of above (3.1) in the state of turning off sprinkle box motor every month, and debug when finding the problem.

2.3 Regularly cleaning electric box, reducing the accumulation of dust, so as not to affect the normal operation of the electrical components.

2.4 Observed crossbeam covers, side beam covers and lifting covers, and the the damaged ones should be replaced in time to avoid water, gas and dust intrusion in the friction of the equipment.

2.5 Hydraulic Station's oil and tank oil should be kept at a certain volume. Often pay attention to observe the oil quasi of the fuel tank, and put it in when oil is lacking.

2.6 Supplementary hydraulic oil must be filtered through 120# mesh.

2.7 Hydraulic oil: In general, 46# hydraulic oil is selected in the summer, 68# hydraulic oil in winter. All should be replaced for half a year.

2.8 Before maintenance, turning off the total power supply and turn off the water switch to o ensure personal safety.